Results 11 to 20 of 78

-

February 19th, 2005 09:03 AM #11

[SIZE=3]Valve Trains[/SIZE]

The valve train consists of the valves and a mechanism that opens and closes them. The opening and closing system is called a camshaft. The camshaft has lobes on it that move the valves up and down.

Most modern engines have what are called overhead cams. This means that the camshaft is located above the valves. The cams on the shaft activate the valves directly or through a very short linkage. Older engines used a camshaft located in the sump near the crankshaft. Rods linked the cam below to valve lifters above the valves. This approach has more moving parts and also causes more lag between the cam's activation of the valve and the valve's subsequent motion. A timing belt or timing chain links the crankshaft to the camshaft so that the valves are in sync with the pistons. The camshaft is geared to turn at one-half the rate of the crankshaft. Many high-performance engines have four valves per cylinder (two for intake, two for exhaust), and this arrangement requires two camshafts per bank of cylinders, hence the phrase "dual overhead cams."

-

February 19th, 2005 09:16 AM #12

[SIZE=3]Ignition System[/SIZE]

The ignition system produces a high-voltage electrical charge and transmits it to the spark plugs via ignition wires. The charge first flows to a distributor, which you can easily find under the hood of most cars. The distributor has one wire going in the center and four, six, or eight wires (depending on the number of cylinders) coming out of it. These ignition wires send the charge to each spark plug. The engine is timed so that only one cylinder receives a spark from the distributor at a time. This approach provides maximum smoothness.

-

February 19th, 2005 09:24 AM #13

[SIZE=3]SPARK PLUGS[/SIZE]

The spark plug is quite simple in theory: It forces electricity to arc across a gap, just like a bolt of lightning. The electricity must be at a very high voltage in order to travel across the gap and create a good spark. Voltage at the spark plug can be anywhere from 40,000 to 100,000 volts.

The spark plug must have an insulated passageway for this high voltage to travel down to the electrode, where it can jump the gap and, from there, be conducted into the engine block and grounded. The plug also has to withstand the extreme heat and pressure inside the cylinder, and must be designed so that deposits from fuel additives do not build up on the plug.

Spark plugs use a ceramic insert to isolate the high voltage at the electrode, ensuring that the spark happens at the tip of the electrode and not anywhere else on the plug; this insert does double-duty by helping to burn off deposits. Ceramic is a fairly poor heat conductor, so the material gets quite hot during operation. This heat helps to burn off deposits from the electrode.

Some cars require a hot plug. This type of plug is designed with a ceramic insert that has a smaller contact area with the metal part of the plug. This reduces the heat transfer from the ceramic, making it run hotter and thus burn away more deposits. Cold plugs are designed with more contact area, so they run cooler.

[SIZE=3]Timing[/SIZE]

The timing of the spark is important, and the timing can either be advanced or retarded depending on conditions.

The time that the fuel takes to burn is roughly constant. But the speed of the pistons increases as the engine speed increases. This means that the faster the engine goes, the earlier the spark has to occur. This is called spark advance: The faster the engine speed, the more advance is required.

Other goals, like minimizing emissions, take priority when maximum power is not required. For instance, by retarding the spark timing (moving the spark closer to the top of the compression stroke), maximum cylinder pressures and temperatures can be reduced. Lowering temperatures helps reduce the formation of nitrogen oxides (NOx), which are a regulated pollutant. Retarding the timing may also eliminate knocking; some cars that have knock sensors will do this automatically.

-

February 19th, 2005 09:29 AM #14

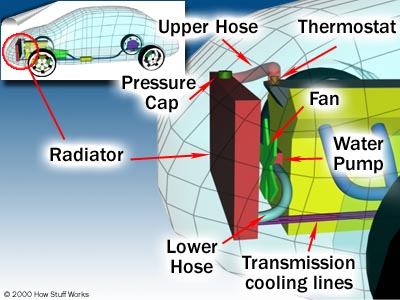

[SIZE=3]Cooling System[/SIZE]

The cooling system in most cars consists of the radiator and water pump. Water circulates through passages around the cylinders and then travels through the radiator to cool it off. In a few cars (most notably Volkswagen Beetles), as well as most motorcycles and lawn mowers, the engine is air-cooled instead (You can tell an air-cooled engine by the fins adorning the outside of each cylinder to help dissipate heat.). Air-cooling makes the engine lighter but hotter, generally decreasing engine life and overall performance.

[SIZE=3]Air Intake System[/SIZE]

Most cars are normally aspirated, which means that air flows through an air filter and directly into the cylinders. High-performance engines are either turbocharged or supercharged, which means that air coming into the engine is first pressurized (so that more air/fuel mixture can be squeezed into each cylinder) to increase performance. The amount of pressurization is called boost. A turbocharger uses a small turbine attached to the exhaust pipe to spin a compressing turbine in the incoming air stream. A supercharger is attached directly to the engine to spin the compressor.

-

February 19th, 2005 09:34 AM #15

[SIZE=3]Starting System[/SIZE]

The starting system consists of an electric starter motor and a starter solenoid. When you turn the ignition key, the starter motor spins the engine a few revolutions so that the combustion process can start. It takes a powerful motor to spin a cold engine. The starter motor must overcome:

* All of the internal friction caused by the piston rings

* The compression pressure of any cylinder(s) that happens to be in the compression stroke

* The energy needed to open and close valves with the camshaft

* All of the "other" things directly attached to the engine, like the water pump, oil pump, alternator, etc.

Because so much energy is needed and because a car uses a 12-volt electrical system, hundreds of amps of electricity must flow into the starter motor. The starter solenoid is essentially a large electronic switch that can handle that much current. When you turn the ignition key, it activates the solenoid to power the motor.

-

February 19th, 2005 09:42 AM #16

[SIZE=3]Lubrication System[/SIZE]

The lubrication system makes sure that every moving part in the engine gets oil so that it can move easily. The two main parts needing oil are the pistons (so they can slide easily in their cylinders) and any bearings that allow things like the crankshaft and camshafts to rotate freely. In most cars, oil is sucked out of the oil pan by the oil pump, run through the oil filter to remove any grit, and then squirted under high pressure onto bearings and the cylinder walls. The oil then trickles down into the sump, where it is collected again and the cycle repeats.

-

February 19th, 2005 09:53 AM #17

[SIZE=3]Fuel System[/SIZE]

The fuel system pumps gas from the gas tank and mixes it with air so that the proper air/fuel mixture can flow into the cylinders. Fuel is delivered in three common ways: carburetion, port fuel injection and direct fuel injection.

* In carburetion, a device called a carburetor mixes gas into air as the air flows into the engine.

* In a fuel-injected engine, the right amount of fuel is injected individually into each cylinder either right above the intake valve (port fuel injection) or directly into the cylinder (direct fuel injection).

-

February 19th, 2005 09:58 AM #18

[SIZE=3]Exhaust System[/SIZE]

The exhaust system includes the exhaust pipe and the muffler. Without a muffler, what you would hear is the sound of thousands of small explosions coming out your tailpipe. A muffler dampens the sound. The exhaust system also includes a catalytic converter.

here are millions of cars on the road in the United States, and each one is potentially a source of air pollution. Especially in large cities, the amount of pollution that all the cars produce together can create big problems.

To solve those problems, cities, states and the federal government create clean-air laws, and many laws have been enacted that restrict the amount of pollution that cars can produce. To keep up with these laws, automakers have made many refinements to car engines and fuel systems. To help reduce the emissions further, they have developed an interesting device called a catalytic converter, which treats the exhaust before it leaves the car and removes a lot of the pollution.

Catalytic converters are amazingly simple devices, so it is incredible to see how big an impact they have!

Last edited by cyberdoc95; February 19th, 2005 at 10:03 AM.

-

February 19th, 2005 11:18 AM #19

[SIZE=3]IGNITION SYSTEM con't[/SIZE]

The DISTRIBUTOR

The distributor handles several jobs. Its first job is to distribute the high voltage from the coil to the correct cylinder. This is done by the cap and rotor. The coil is connected to the rotor, which spins inside the cap. The rotor spins past a series of contacts, one contact per cylinder. As the tip of the rotor passes each contact, a high-voltage pulse comes from the coil. The pulse arcs across the small gap between the rotor and the contact (they don't actually touch) and then continues down the spark-plug wire to the spark plug on the appropriate cylinder. When you do a tune-up, one of the things you replace on your engine is the cap and rotor -- these eventually wear out because of the arcing. Also, the spark-plug wires eventually wear out and lose some of their electrical insulation. This can be the cause of some very mysterious engine problems.

Older distributors with breaker points have another section in the bottom half of the distributor -- this section does the job of breaking the current to the coil. The ground side of the coil is connected to the breaker points.

A. CONNECTION TO COIL

B. BREAKER POINTS

C. ADJUSTMENT SCREW

D. CAM FOLLOWER

E. DISTRIBUTOR CAM

F. CONDENSER

A cam in the center of the distributor pushes a lever connected to one of the points. Whenever the cam pushes the lever, it opens the points. This causes the coil to suddenly lose its ground, generating a high-voltage pulse.

The points also control the timing of the spark. They may have a vacuum advance or a centrifugal advance. These mechanisms advance the timing in proportion to engine load or engine speed.

Spark timing is so critical to an engine's performance that most cars don't use points. Instead, they use a sensor that tells the engine control unit (ECU) the exact position of the pistons. The engine computer then controls a transistor that opens and closes the current to the coil.

Last edited by cyberdoc95; February 19th, 2005 at 11:38 AM.

-

February 19th, 2005 11:25 AM #20

[SIZE=3]IGNITION SYSTEM con't[/SIZE]

Solid State Ignition

In recent years, you may have heard of cars that need their first tune-up at 100,000 miles. One of the technologies that enables this long maintenance interval is the distributorless ignition.

The coil in this type of system works the same way as the larger, centrally-located coils. The engine control unit controls the transistors that break the ground side of the circuit, which generates the spark. This gives the ECU total control over spark timing.

Systems like these have some substantial advantages. First, there is no distributor, which is an item that eventually wears out. Also, there are no high-voltage spark-plug wires, which also wear out. And finally, they allow for more precise control of the spark timing, which can improve efficiency, emissions and increase the overall power of a car.

Reply With Quote

Reply With Quote

Be careful with channels like "China Observer" on YouTube. There is a clear bias in their posts and...

Xiaomi E-Car